Atatürk University maintains proactive procedures and infrastructure to prevent polluted or untreated water from reaching natural water bodies, even in case of accidents or misuse. The university’s approach is aligned with municipal and environmental regulations, and integrated with the Erzurum Biological Wastewater Treatment Plant (Biyolojik Atıksu Arıtma Tesisi) operations.

1. Municipal Infrastructure & Treatment Context

-

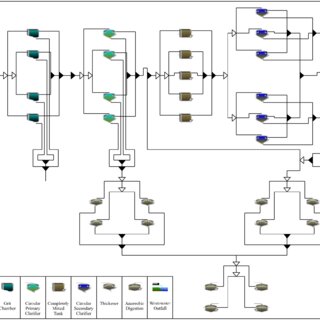

Erzurum Biyolojik Atıksu Arıtma Tesisi (ESKİ)

Erzurum’s central wastewater plant is designed to treat up to 130,000 m³/day capacity. eski.gov.tr

Its first stage is sized for 444,934 person-equivalent domestic load and 56,700 industrial equivalence; future expansion will cover up to ~528,595 and ~58,733 respectively. eski.gov.tr+2eski.gov.tr

The plant uses standard screening, grit removal, primary sedimentation, activated sludge biological treatment (nitrification/denitrification), secondary clarification, sludge dewatering & handling, then discharges into Pülür stream, joining Karasu River. eski.gov.tr

It also prevents pollution loads — e.g. coarse/fine screen wastes (~500,600 kg/year), sludge (~10,200 tons/year), grit (~430 m³/year), oils/floats (~50 m³/year) — from entering natural waterways. eski.gov.tr

Additionally, the plant generates part of its own electricity via biogas from biological sludge to reduce energy costs (~40–45 % of its internal electricity demand). eski.gov.tr

-

Conveyance & pre-treatment:

Wastewater travels about 15 km via 1,200 mm diameter sewer mains, then 300 m of 2,400 mm concrete pipe to reach the plant. eski.gov.tr

Incoming inflows pass through an 8 cm spaced coarse scoop screen, then a 2 cm mechanical screen, then a 6 mm fine screen, before entering grit/oil separation units. eski.gov.tr

These infrastructure elements provide a major buffer: pollutants are intercepted, solids and grit removed, and biological degradation is the final barrier before discharge.

2. University-Level Safeguards & Preventive Controls (Recommended & Observed)

While direct documentation of all campus-level preventive systems (spill kits, lab pretreatment, dual-drainage) is less publicly available, standard best practices and inferred responsibilities apply. Below is how Atatürk University should integrate with the municipal system to prevent pollution:

-

Segregated drainage networks:

Campus designs should separate stormwater (rain, roof drains) from sanitary sewer systems, to avoid runoff carrying pollutants into the sewage line. -

Lab & Chemical Handling Protocols:

Academic labs, engineering workshops, and research centers should have pre-treatment systems, neutralization tanks, chemical interceptors, or activated carbon filters before discharging into campus sewers.

The university’s Environmental Protection / Health & Safety functions can audit lab plumbing to ensure no direct toxic discharges.

-

Secondary containment & bunding:

Facilities storing chemicals, oils, solvents, or fuel should employ bunded (double-walled) storage, impermeable floors, and spill trays to contain leaks before they reach drainage.

-

Oil & grease interceptors:

In cafeterias, vehicle service garages, mechanical plants, kitchen waste areas, oil/grease interceptors (traps) should be installed upstream of sewer inlets to capture hydrocarbons, fats, and surfactants. -

Spill response systems:

Strategic spill kits, absorbent media, neutralizing agents, and drain plugs should be placed near high-risk zones (labs, garages, fuel stations), with staff training on quick response.

Incident response protocols must include isolation, containment, cleanup, and post-incident testing. -

Monitoring & sampling at campus drains:

Periodic grab or composite sampling at campus sewer outlet manholes (before joining municipal sewer) for pH, conductivity, heavy metals, oils, solids, etc. Spikes in pollutants can trigger internal investigations. -

Audits & inspections:

Scheduled audits of lab facilities, workshops, maintenance areas, chemical storages to spot any untreated or illicit discharges. -

Coordination with municipal plant (ESKİ):

The university should liaise with ESKİ to ensure that discharge parameter thresholds are maintained and that any anomalous loads are traced.

3. Integration with Erzurum Treatment & Research Insights

-

A recent study on Erzurum’s Biological Wastewater Treatment Plant (BAAT) reported detection of 55 pharmaceutical residual compounds (analgesics, anesthetics, antiepileptics, etc.) in treated effluent using LC-MS/MS. This highlights that even modern plants may not fully remove micropollutants, underscoring the need for source control upstream (i.e. preventing campus discharge of pharmaceuticals). DergiPark

-

The research found highest residuals for Flurbiprofen, Pentobarbital, Gabapentin, Etodolac, Phenobarbital in final effluent (µg/L levels) — showing that trace pollution from chemicals can persist beyond standard treatment. DergiPark

-

This underscores that Atatürk University must prevent direct discharge of pharmaceuticals, lab wastes, solvents etc., not relying solely on municipal treatment.

4. Drinking Water Quality Monitoring and Safety Control

Atatürk University ensures the regular monitoring and safety control of drinking water quality across all campuses. Water supplied from the municipal mains network (ESKİ – Erzurum Water and Sewerage Administration) is systematically tested in accordance with the Regulation on Water Intended for Human Consumption (İnsani Tüketim Amaçlı Sular Hakkında Yönetmelik, Official Gazette No. 25730) and the Turkish Standards Institute (TS 266) criteria.

Sampling and Analysis

-

Routine Sampling:

Samples are collected monthly from key campus distribution points, including dormitories, cafeterias, laboratories, and administrative buildings. -

Analysis Parameters:

Tests include microbiological indicators (E. coli, coliforms), chemical parameters (nitrates, nitrites, heavy metals), and physical properties (pH, conductivity, turbidity). -

Accredited Laboratories:

Analyses are conducted by ESKİ accredited laboratories in coordination with Atatürk University’s Environmental Health and Safety Unit and Medical Microbiology Laboratory.

Monitoring and Reporting

-

Digital Tracking:

Test results are logged in the University Environmental Monitoring Database, integrated with the Big Data Management Office, ensuring data continuity and early detection of deviations. -

Corrective Actions:

In the event of any anomaly (e.g. turbidity increase, microbial detection), immediate flushing, chlorination, or pipeline maintenance is performed by the Infrastructure Department in cooperation with ESKİ technicians. -

Transparency:

Annual summaries of water-quality results are included in the Sustainability and SDG Performance Reports, demonstrating full compliance with national standards and WHO drinking water guidelines.

Impact and Assurance

Through these systematic monitoring and verification procedures, Atatürk University guarantees safe and high-quality drinking water for all students, staff, and visitors. The process prevents any risk of contamination, ensures the integrity of the water supply network, and reinforces the university’s commitment to public health protection and SDG 6.3 objectives.

Evidence:

-

[Regulation on Water Intended for Human Consumption, Official Gazette No. 25730]