Atatürk University ensures that all campus wastewater is collected, conveyed, and treated before discharge into the environment. Our wastewater management process is fully integrated into the municipal treatment infrastructure of Erzurum, using the city’s advanced Biological Wastewater Treatment Plant. This ensures compliance with national and environmental standards, and demonstrates institutional responsibility for water quality and ecosystem protection.

1. Collection & Conveyance of Wastewater

-

Campus Sewer Network Connection:

All buildings, laboratories, dormitories, and campus facilities are connected to the municipal sewer system. University wastewater is not discharged untreated locally but is conveyed via public sewer infrastructure. -

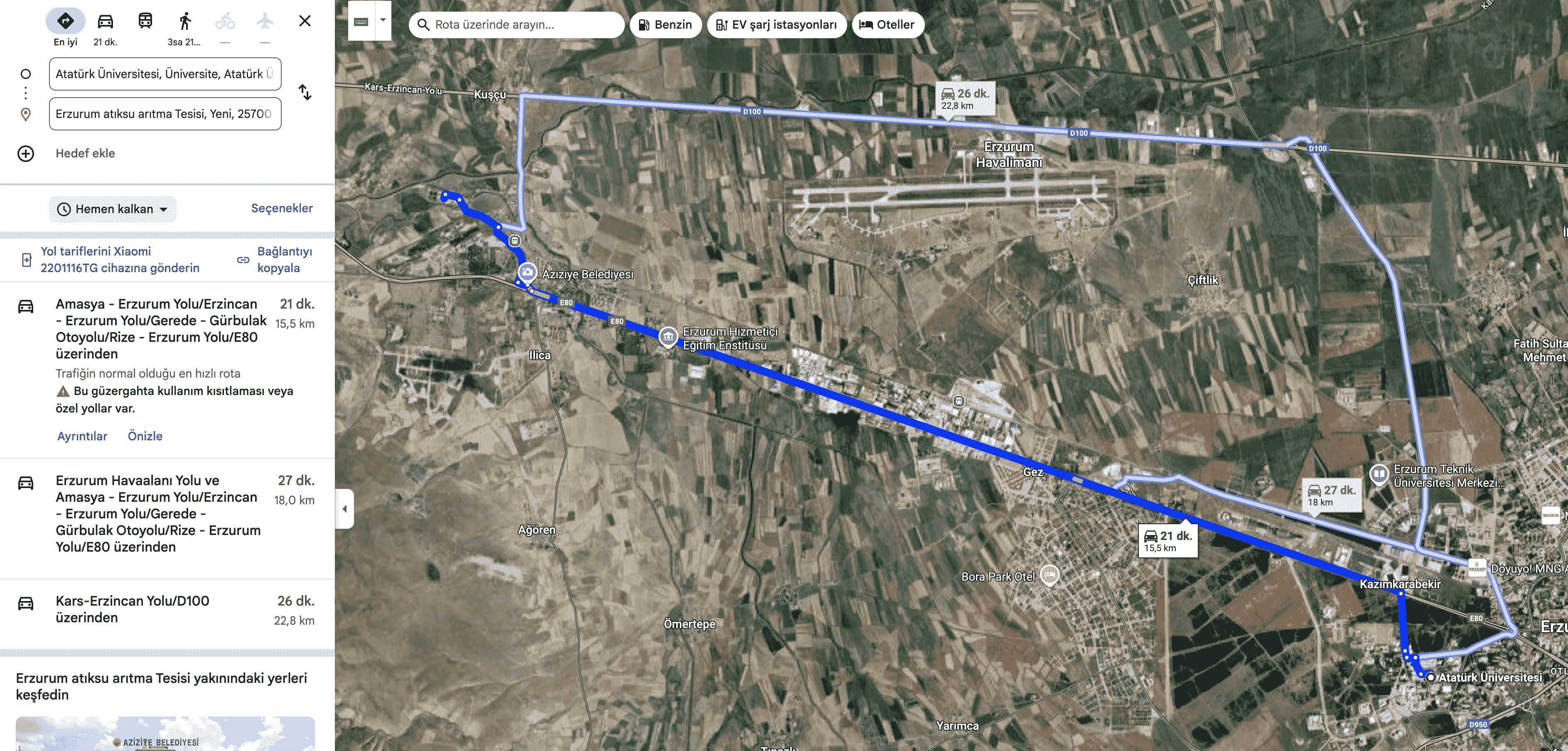

Transport to Treatment Plant:

The wastewater collected across campus is transported approximately 15 km through 1200 mm diameter sewer mains, feeding into a 2,400 mm diameter, 300 m concrete pipeline section before reaching the Erzurum Biological Wastewater Treatment facility.

eski.gov.tr

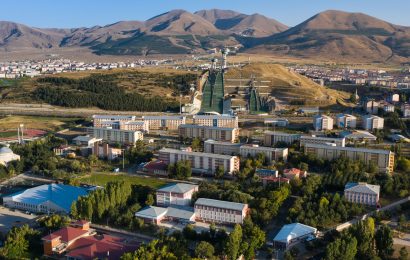

2. Erzurum Biological Wastewater Treatment Plant (Biyolojik Atıksu Arıtma Tesisi)

The central wastewater treatment facility serving the city, including Atatürk University’s effluent, uses modern biological treatment processes:

-

Location & Capacity:

The plant is located in Ilıca / Aziziye region, near Kuşçu Village, adjacent to Ferah neighborhood. It was commissioned in 2015 and taken under operation by ESKİ (Erzurum Su & Kanalizasyon İdaresi). eski.gov.tr

It is designed to handle up to 130,000 m³/day of wastewater under maximum loading. eski.gov.tr

Its first stage capacity corresponds to servicing a residential population of ~444,934 people and industrial capacity for ~56,700 persons. eski.gov.tr

Future expansion (2nd stage) is designed for ~528,595 residential plus ~58,733 industrial equivalents. eski.gov.tr -

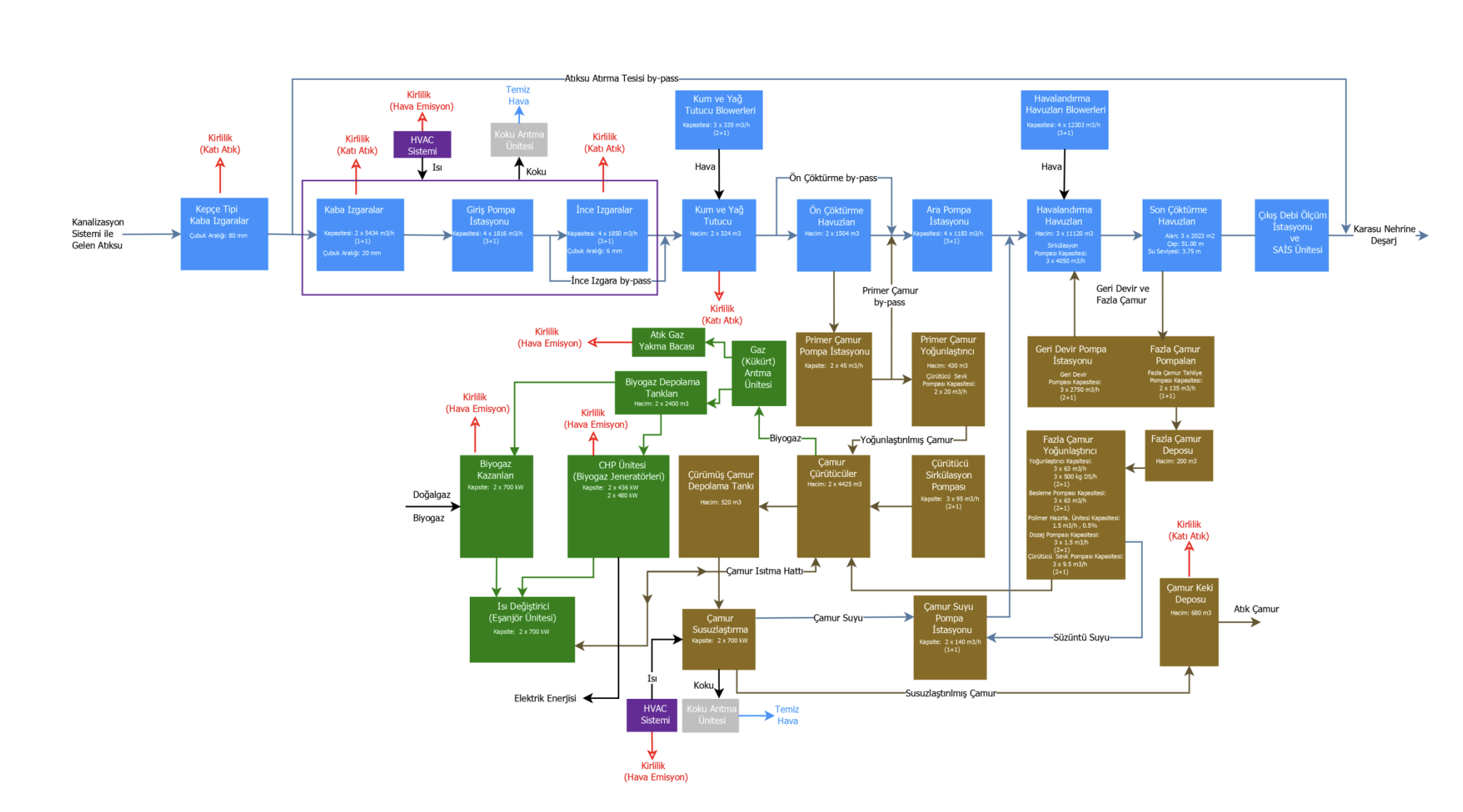

Treatment Process & Unit Operations:

-

-

Coarse Screening / Bar Screens: Incoming wastewater passes through a kaba ızgara (8 cm spaced scoop bar screen), followed by a mechanical coarse screen (2 cm spacing) to remove large solids. eski.gov.tr

-

Pumping / Preliminary Lift: Wastewater is lifted via terfi pompaları (~6.8 m lift) to maintain flow continuity. eski.gov.tr

-

Fine Screening: An automated fine screen (6 mm spacing) removes finer solids to protect mechanical equipment. eski.gov.tr

-

Grit and Oil Removal: In a two-chamber aerated grit-oil removal unit, heavier particles (sand/grit) settle and lighter substances (oil, foams) are skimmed off. eski.gov.tr

-

Primary Sedimentation (Pre-settling): Wastewater enters primary clarifiers where heavier solids settle. eski.gov.tr

-

Biological Treatment (Activated Sludge / Nitrification-Denitrification): After preliminary treatment, water is moved into aeration tanks where organic carbon and nitrogen compounds are processed via bacterial degradation (nitrification-denitrification). eski.gov.tr

-

Secondary Clarification: Effluent from aeration flows to secondary settling tanks, where biomass (activated sludge) settles out. eski.gov.tr

-

Sludge Handling / Dewatering: Settled sludge is transported to sludge treatment facilities; excess sludge is further processed, and stabilized sludge is managed in the Çamur Binası (sludge building). eski.gov.tr

-

Final Discharge: Treated effluent is released into Pülür stream, which flows into the Karasu River. eski.gov.tr

-

-

Performance & Pollutant Removal:

The plant is dimensioned per ATV-DVWK standards (ATV 131-E), targeting removal of carbonaceous substances, nitrogen, phosphorus, and other pollutants. eski.gov.tr

According to reports, the plant processes about 26,600,000 m³/year of wastewater to meet discharge standards. eski.gov.tr

By-product statistics: ~10,200 tons/year of biological sludge; ~500,600 kg/year of coarse & fine screening wastes; ~430 m³/year of grit; and ~50 m³/year of oils/floats are prevented from discharging into Karasu River. eski.gov.tr -

Upgrades & Efficiency Improvements:

In October 2024, diffuser replacement and revision works in aeration basins were completed, expected to reduce electrical consumption by 40–50 %. eski.gov.tr

Mechanical equipment (screens, conveyors, penstocks) are subject to ongoing maintenance and upgrades. eski.gov.tr

3. Institutional Roles, Monitoring & Quality Assurance

-

University Oversight & Coordination:

Atatürk University’s Big Data Management Office and Department of Construction and Technical Affairs coordinate with municipal operators (ESKİ) to ensure campus wastewater is properly conveyed to the treatment plant and that the discharge meets required permits. -

Monitoring & Sampling:

At discharge points or manholes near campus, the university periodically collects samples (flow-weighted composite or grab) to monitor BOD, COD, TSS, nitrogen, phosphorus, and pH. -

Compliance & Reporting:

The university requires municipal operator (ESKİ) to submit water quality certificates and discharge compliance reports, which are archived by the university for internal audit and external stakeholders. -

Continuous Improvement & Collaboration:

-

Joint audits with ESKİ to identify infiltration, leaks, or illicit connections.

-

Campus-based pretreatment (e.g., neutralization, oil separators) required for labs or industrial units before entering the sewer.

-

Training for faculty, labs, and maintenance units on proper waste disposal to avoid harmful substances entering campus sewers.

-